Showroom

Nano Grinding Mills are used in industrial sector for grinding diverse types of materials into fine particles. These are facilitated with longer shelf life, noise free functions, simple usage, reliability and high performance efficiency.

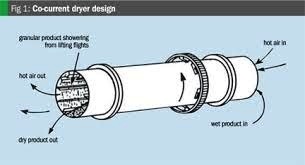

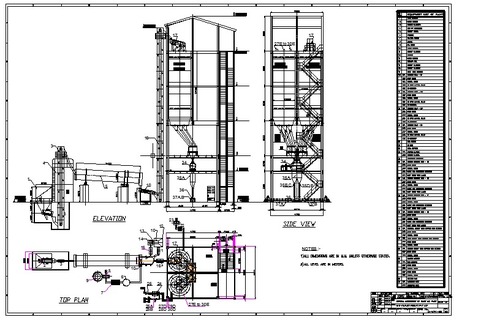

This range of Rotary Dryer is smooth functioning, noiseless, durable, easy to operate and erosion resistant. It is known for its efficiency in converting several types of materials into powder form.

|

KINC Mineral Technologies Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |